What does “recycled” mean anyway?

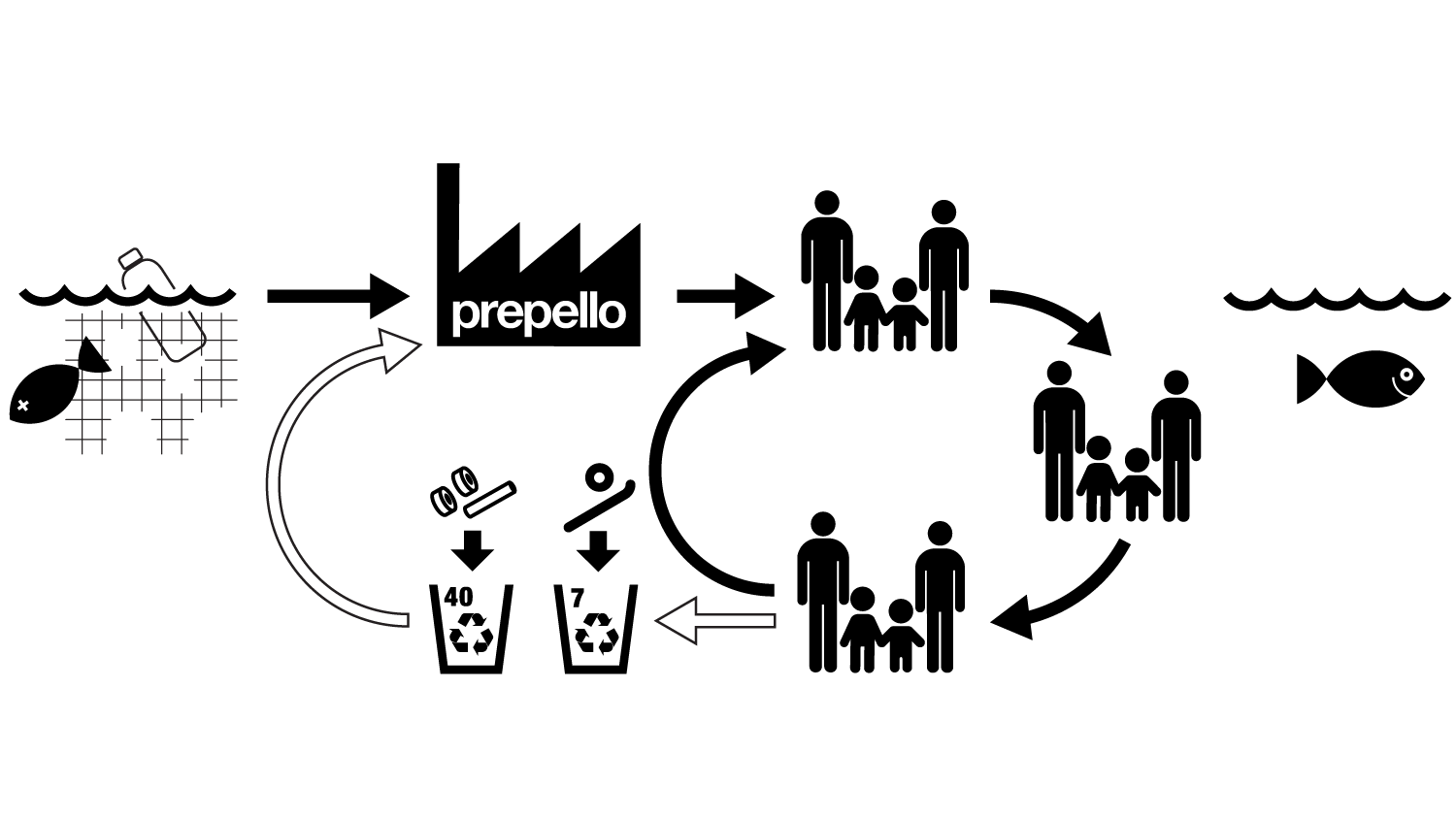

The prepello deck is made of 100% post-consumer recycled plastic (+fiber) of which most comes from discarded fishing nets. For every board, you help collect about 0.5 kg plastic waste from nature and stop up to 1 kg* of new virgin plastic from being produced from petroleum/fossil fuels and released onto the market.

*estimated average amount in competitor products.

Post- vs. Pre-consumer.

Today most companies are trying to clean up their act when it comes to sustainability. This is great, but it also makes it hard for consumers to separate real efforts from plain green washing. It may be a good idea to know the difference between following commonly used terms:

Recyclable: A very loose term since it only indicates that it is theoretically possible to recycle the material in a product after its been used. Whether it’s actually done or not, is outside the producers control and largely up to the end user and the nations general recycling infrastructure.

Recycled: Used to describe either of the two following grades, commonly the first one.

Pre-consumer: This refers to material that has been salvaged somewhere within the production process, and then re-entered in the same process. Also known as “industry scrap”. So, in some sense it can still be considered “new” material.

Post-consumer: This is material that has actually been used in the form of another product before being re-used again as production material. This is what we mentally picture when seeing something labeled “recycled”, however in reality it’s seldom the case.

Prepello uses fiber enhanced 100% post-consumer PA (polyamid) in our board deck, and virgin PP/PU in our wheels. Our suppliers are GRS (Global Recycled Standard) certified by third party.

Why are not more companies doing it?

Because it’s difficult. Because it’s expensive.

Each time plastic goes through the product production process, it loses some of its performance. Therefore, in general, recycled plastics are of poorer quality than virgin material. So simply switching to recycled material in your exciting product & process is very likely to fail.

Furthermore, post-consumer materials first need to be collected, sorted, cleaned, and finally turned into pellets again before it can be sold as raw material. This makes it up to 3 times more expensive as new material (PA). Basically, you’re getting lower performance to a much higher price.

We at prepello have overcome these two problems in two ways:

Since prepello had an absolute focus on sustainability from day one, we have been able to adapt the product design and production process to the properties of recycled materials from the very beginning.

And by being transparent with you as a customer, we believe that you are willing to pay a slightly higher price, knowing the importance of making educated sustainable choices.

Plastic is fantastic… or is it?

Great performance. Low cost. Super durable. This is also the problem: It can take hundreds of years for plastics to break down, if at all.

Plastics have only really existed for the last 60-70 years, but in that time, it has transformed everything from packaging to product design and retailing. And plastic waste has become a major environmental hazard. From landfills to micro-plastics and ghost-nets in the ocean.

When prepello uses old fishing nets in our products, we not only keep the oceans clean from ghost-nets, but also prevents new virgin plastic to be produced and put onto the market in the shape of other products. Read more about the impact of plastic waste and the importance of marine wild live below:

Not there yet.

As you probably can tell by now, we are extremely proud of having managed to implement post-consumer plastics in our product. Numerous manufacturers and suppliers have urged us to “just take the easy way” because post-consumer PA will only bring more work and higher cost. But that is exactly why it’s so important:

The more companies that demand recycled materials throughout the supply chain, the easier (and cheaper) it will become to source it. Today the infrastructure is simply not there. Small companies are too small to get served and really large companies cannot attain large enough supply. Pushing for market demand for recycled material just might be the most important effort we do.

It’s worth mentioning that for some plastics and applications, the collection infrastructure, recycling industry, sourcing network and market demand are already in place. This is the case for PET bottles in many countries (but far from all), where purchasing of post-consumer PET material is relatively easy. This is great, and this is what we should aim for regarding all materials (and all countries).

However, we have yet to implement recycled materials in our wheels. Our purchasing power simply was too small. Furthermore, we cater for the European market, yet produce in China. This is not optimal for many reasons. We haven’t managed to find recycled material and production willing to take the risk locally yet. This, and much more, are things we will improve as we grow and learn.

We are far from perfect, as company as well as individuals. But we’re trying. Hard.